Comprehensive Energy Optimization for a Large Edible Oil Refinery

SEE-Tech Solutions conducted a comprehensive energy audit and implemented advanced energy conservation measures for a large edible oil refinery, achieving significant reductions in electricity and thermal energy consumption with rapid payback.

Project Specs

- Client

- Industry

- Edible Oil Manufacturing & Processing

- Technologies

- Energy AuditIndustrial Energy EfficiencySteam OptimizationIE5 MotorsVacuum System OptimizationWaste Heat RecoverySustainability

The Challenge

Our Solution

The Results

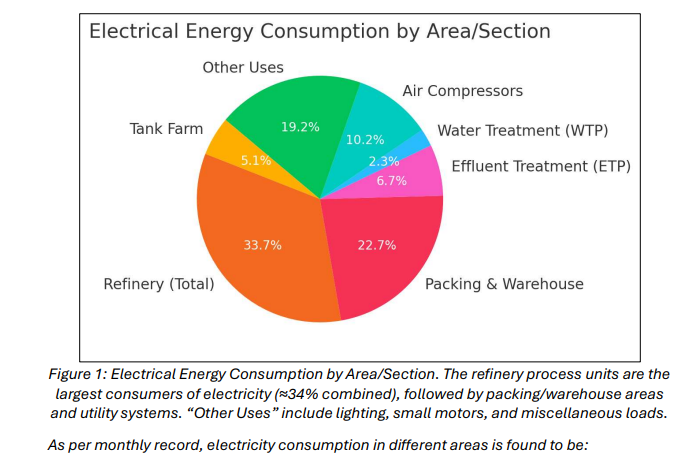

SEE-Tech Solutions successfully executed a comprehensive energy audit and optimization study for a large edible oil refining and processing facility operating at partial capacity with high electrical and thermal energy demand. The objective of the engagement was to identify energy conservation opportunities, reduce operating costs, and create a clear implementation roadmap without impacting production throughput, product quality, or plant reliability.

The facility included multiple energy-intensive operations such as crude oil refining, deodorization, fractionation, hydrogenation, tank farm heating, packaging, and extensive utility systems including boilers, chillers, compressors, pumps, and vacuum systems. Energy costs represented a significant portion of the total manufacturing cost, making efficiency improvement a strategic priority.

4

Energy Challenges Identified

During detailed site studies, data logging, and system-level analysis, several critical inefficiencies were identified:

Heavy dependence on coal-based steam generation for process heating and vacuum systems

Extensive use of steam ejector-based vacuum systems with high steam consumption

Under-loaded motors and pumps operating at throttled conditions

Low condensate recovery levels (~30%), leading to water and heat losses

Significant heat losses from uninsulated tanks, valves, and steam pipelines

High electricity usage in chillers, cooling towers, and compressed air systems

Partial utilization of existing VFDs due to improper control strategies

These issues resulted in avoidable energy wastage, higher fuel consumption, increased emissions, and elevated operating costs.

Steam Distribution

1.1 Refinery: PTP 1 Deodorizer

1.1 Refinery: PTP 1 Deodorizer with its Utilities

4

SEE-Tech Solutions Approach

SEE-Tech Solutions carried out a plant-wide, system-based energy audit covering:

Electrical systems (motors, pumps, drives, and distribution)

Steam generation, distribution, and condensate recovery

Process vacuum systems in refining and deodorization

Cooling systems including chillers and cooling towers

Compressed air systems and plant utilities

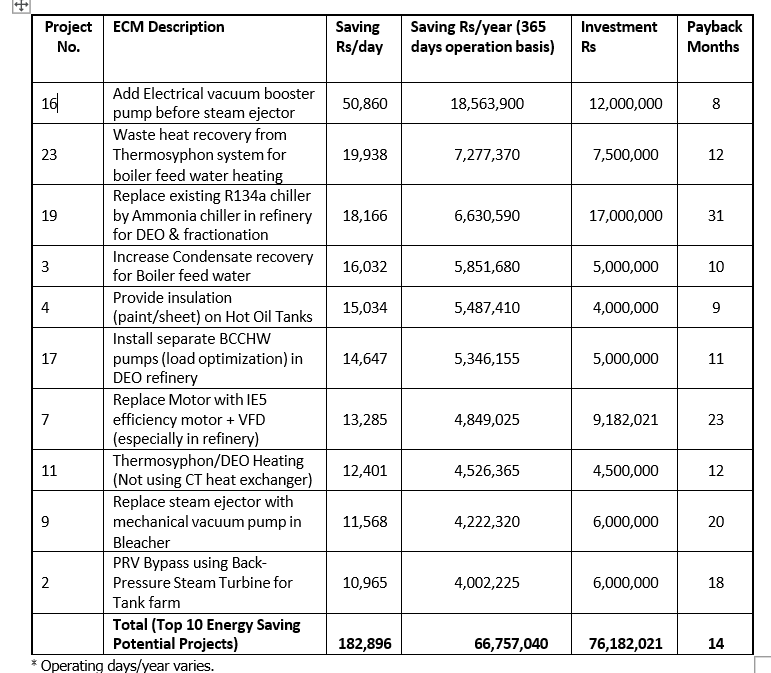

Based on measured data and performance benchmarking, a set of Energy Conservation Measures (ECMs) was developed with detailed savings calculations, investment estimates, and payback analysis.

Key recommended solutions included:

Replacement of inefficient and under-loaded motors with IE5 ultra-premium efficiency motors combined with VFD-based speed control

Conversion of steam ejector vacuum systems to hybrid or fully mechanical vacuum systems, significantly reducing steam consumption

Waste heat recovery from fired heaters and thermosyphon systems to preheat boiler feedwater

Installation of back-pressure steam turbines in place of pressure-reducing valves for power generation

Improvement of condensate recovery systems across process and tank farm areas

Comprehensive thermal insulation of hot oil tanks, steam lines, and valves

Optimization of chillers, cooling towers, and compressed air systems through control logic improvements and load matching

Immediate zero-capex operational improvements, such as eliminating throttling losses and optimizing combustion parameters

Optimization of ejector based vacuum system for DO

Surface condenser CW pump (To be replaced by low pressure pump/run at frequency G PHE value by a new pump)

Install two separate BCCHW pump for 1/3 G 2/3 Ejector

Install two separate BCCHW pump for 1/3 G 2/3 Ejector

Refinery: Fraction chiller issues (Install VFD on chiller on both compressor)

Results & Impact

The audit identified 35+ energy conservation opportunities, delivering a total savings potential exceeding ₹9 crore per year, with an average payback period of approximately 12 months.

Key outcomes included:

Reduction of electricity consumption by ~10,000 kWh per day

Reduction in coal consumption by ~10–12 tons per day

Improvement in overall plant energy efficiency by up to 20%

Estimated annual CO₂ emission reduction of over 10,000 tons

Improved reliability and lifespan of motors, pumps, and utility equipment

Enhanced process control and vacuum stability in refining operations

Reduced water consumption and effluent load through improved condensate recovery

A phased implementation roadmap was delivered, enabling the client to prioritize quick-return projects while planning larger capital investments strategically.

Conclusion

This project demonstrates SEE-Tech Solutions’ capability to deliver high-impact, data-driven energy efficiency solutions for large industrial facilities. By combining deep technical expertise with practical implementation strategies, the project enabled substantial cost reduction, improved sustainability performance, and long-term operational resilience—without compromising production or quality.