Energy Saving Opportunities in AHU, Motors & Other Plant Equipment

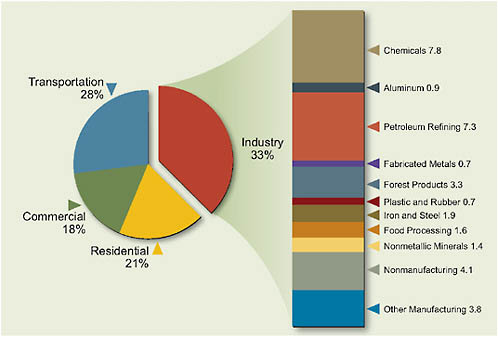

SEE-Tech Solutions conducted an investment-grade energy audit focused on AHUs, chillers, motors, air compressors, and pumps at a manufacturing facility in Hyderabad, identifying energy saving opportunities delivering up to 22% reduction in overall electricity consumption.

Project Specs

- Client

- Industry

- Manufacturing – Utility-Intensive Industrial Facility

- Technologies

- Energy AuditAHU OptimizationChiller EfficiencyIE5 MotorsAir Compressor OptimizationPump EfficiencySustainability

The Challenge

Our Solution

The Results

The investment-grade energy audit conducted at Pravesha Industries Pvt. Ltd., Hyderabad Plant (Unit-1) identified five major energy saving projects covering approximately 81% of total plant electricity consumption. The recommended measures together deliver a 22% reduction in overall energy consumption, translating into ₹56.5 lakh per year in cost savings with a total investment of ₹1.09 crore and a weighted average payback of 23 months

.

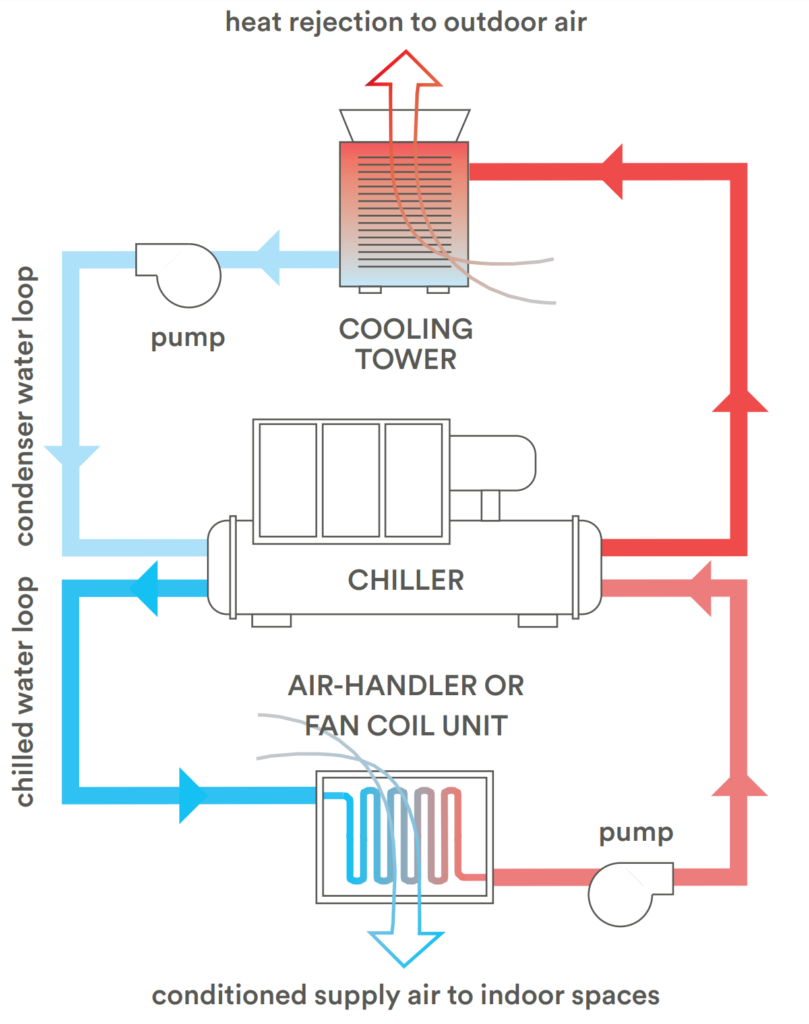

1. Chiller System Optimization (12% Overall Energy Saving)

Chillers were the largest energy consumer, accounting for 35.6% of total plant electricity usage. Two high-impact retrofit opportunities were identified:

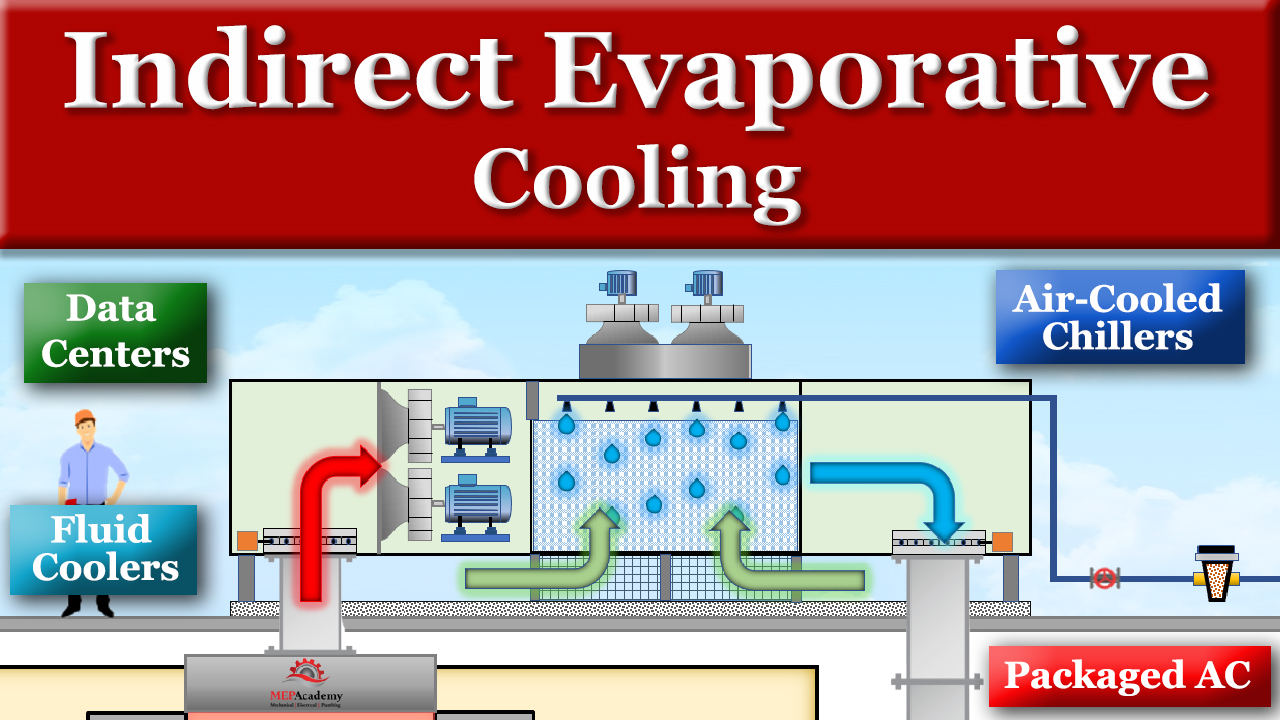

a) Static to Adiabatic Cooling Retrofit

Annual savings: ₹15.53 lakh

Investment: ₹12.5 lakh

Payback: ~10 months

Adiabatic cooling reduces the inlet air temperature to the air-cooled chillers by 5–10°C, significantly lowering compressor lift and improving COP during high ambient conditions.

b) Static to Variable Speed (VFD) Compressors

Annual savings: ₹15.53 lakh

Investment: ₹37.5 lakh

Payback: ~29 months

VFD-enabled compressors improve part-load efficiency and reduce frequent start-stop losses. The audit confirmed that similar savings could be achieved through this retrofit at one-third the cost of installing a new water-cooled chiller

.

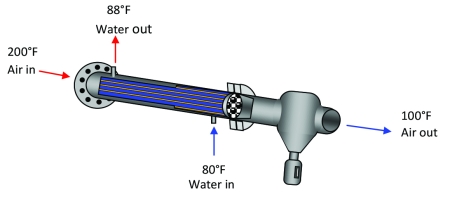

2. Air Compressor Optimization (1.4% Overall Energy Saving)

Air compressors contributed ~16.6–17% of plant energy consumption. The audit identified high suction air temperature as a major inefficiency.

Solution: Indirect evaporative cooling of suction air

Temperature reduction: 5–12°C

Annual savings: ₹3.62 lakh

Investment: ₹2.0 lakh

Payback: ~7 months

Lower suction temperature increases air density, reduces compression work, and improves compressor reliability while delivering fast financial returns

.

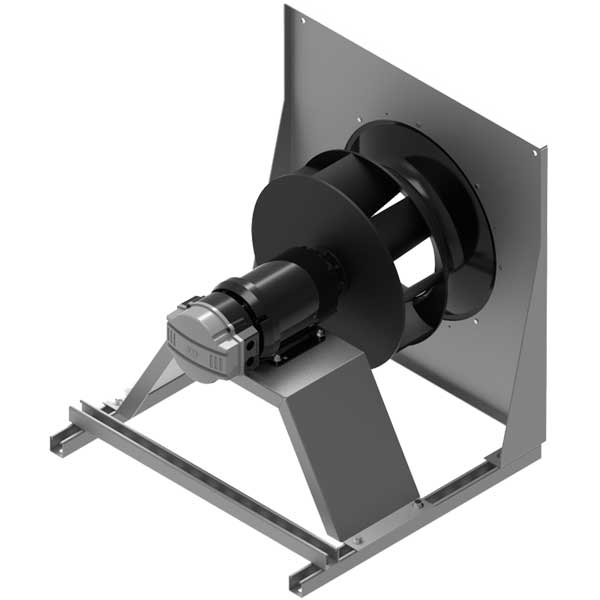

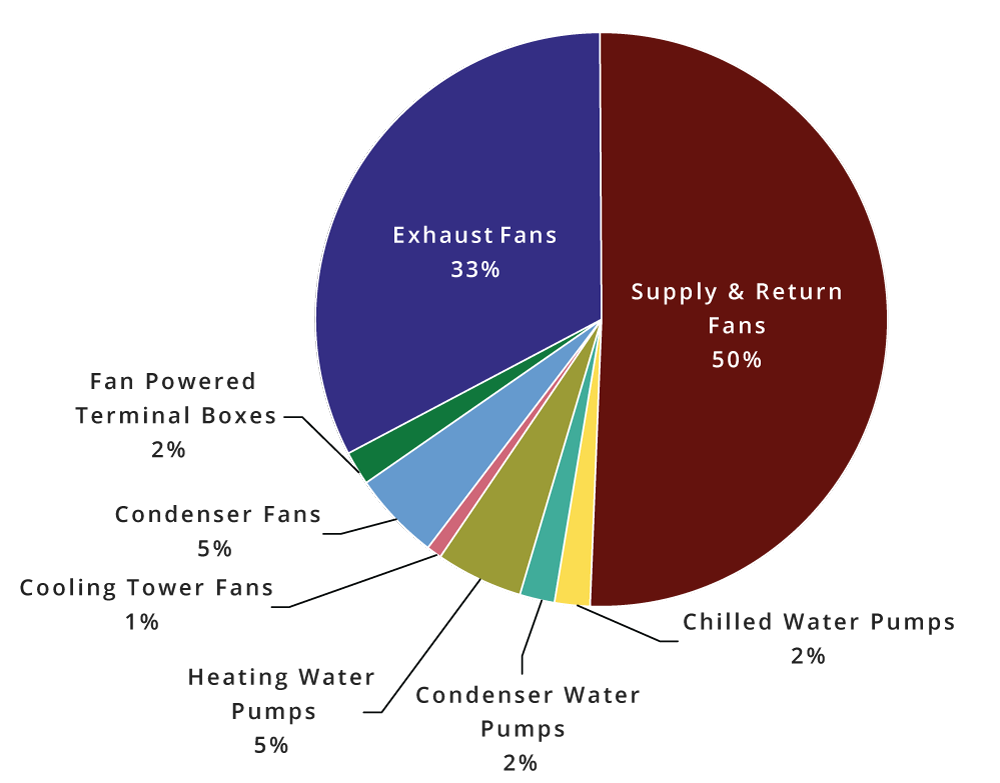

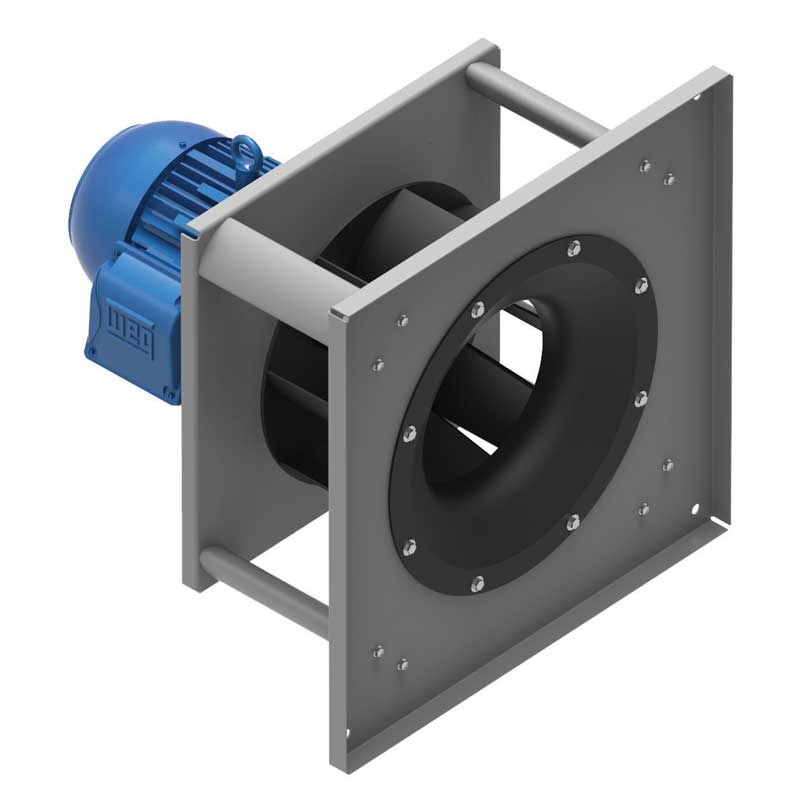

3. AHU Fan Retrofit with IE5 Motors (6.8% Overall Energy Saving)

AHUs accounted for 20.8% of total electricity consumption. Existing belt-driven centrifugal fans were replaced with direct-drive aerofoil plug fans powered by IE5-efficiency motors.

AHU blower energy consumption: 7.38 lakh kWh/year

Energy saving achieved: ~40%

Annual savings: ₹17.69 lakh

Investment: ₹44.7 lakh

Payback: ~30 months

Additional benefits included elimination of belt losses, reduced maintenance, lower noise levels, and improved airflow control with VFD compatibility .

4. Pump Efficiency Improvement (1.6% Overall Energy Saving)

Pumps contributed ~7.6% of total electricity consumption. Many pumps were found operating near full load with standard efficiency motors.

Solution: Replacement with energy-efficient pumps driven by IE5 motors

Energy saving: ~25% in pumping systems

Annual savings: ₹4.13 lakh

Investment: ₹12.5 lakh

Payback: ~36 months

This upgrade improves hydraulic efficiency, reduces motor losses, and increases equipment life

Energy Audit Report Pravesha Un…

.

5. Overall Energy & Financial Impact

ParameterResultEnergy Consumption Covered81%Total Energy Saving22%Annual Cost Savings₹56.5 lakhTotal Investment₹1.09 croreAverage Payback23 months

Energy savings contribution by system:

Chillers: 12%

AHUs: 6.8%

Air Compressors: 1.4%

Pumps: 1.6%

The recommended projects collectively improve system reliability, reduce maintenance burden, and significantly lower the plant’s carbon footprint while ensuring operational continuity

.

Conclusion

The detailed results demonstrate that utility-focused energy optimization can deliver substantial savings with proven technologies such as adiabatic cooling, VFDs, IE5 motors, and plug fan retrofits. The Pravesha Industries Unit-1 audit provides a clear, data-driven roadmap to achieve rapid payback, sustained cost reduction, and long-term energy efficiency improvement.