Investment Grade Energy Audit & Optimization for a Plastic Injection Moulding Facility

SEE-Tech Solutions conducted an investment-grade energy audit at a large plastic injection moulding facility, identifying high-impact energy conservation measures across dryers, moulding machines, HVAC, compressors, and utilities—delivering significant cost savings with a structured implementation roadmap.

Project Specs

- Client

- Industry

- Plastic Injection Moulding Manufacturing

- Technologies

- Energy AuditInjection MouldingHeat RecoveryIE5 MotorsDryer OptimizationCompressed AirSustainability

The Challenge

Our Solution

The Results

SEE-Tech Solutions carried out an investment-grade energy audit for a large plastic injection moulding manufacturing facility operating multiple high-capacity injection moulding machines supported by energy-intensive utility systems. The objective of the engagement was to identify measurable energy-saving opportunities, reduce operating costs, and develop a clear, prioritized implementation roadmap without affecting production quality, machine reliability, or throughput.

The facility operates on a continuous production model, with energy consumption dominated by injection moulding machines, hot air dryers, dehumidifiers, compressors, chillers, and HVAC systems. Electricity accounted for a major portion of operating expenses, making energy efficiency a strategic business requirement rather than just a compliance activity.

4

Process & Energy Challenges

Detailed site measurements, data logging, and system analysis revealed several key inefficiencies:

High electricity consumption from Husky injection moulding machines and dryers

Significant heat loss from hot air dryer exhaust and machine heating zones

Under-loaded motors operating far below optimal efficiency

Moisture recirculation on the shop floor increasing dehumidifier energy demand

Inefficient cooling methods adding humidity instead of removing it

Elevated compressor energy consumption due to high suction air temperature

Lack of coordinated control between utilities and production load variations

These issues resulted in avoidable energy wastage, higher production costs, and increased carbon emissions.

4

SEE-Tech Solutions Approach

SEE-Tech Solutions adopted a system-level, data-driven audit methodology, covering:

Injection moulding machines and auxiliaries

Hot air dryers and dehumidification systems

HVAC and air washer systems

Air compressors and compressed air distribution

Chillers, cooling towers, and pumping systems

Each system was evaluated based on actual operating conditions, not nameplate ratings. Energy Conservation Measures (ECMs) were developed with measured data, savings calculations, investment estimates, and payback periods.

Key solutions included:

Heat recovery from hot air dryers using air-to-air heat exchangers

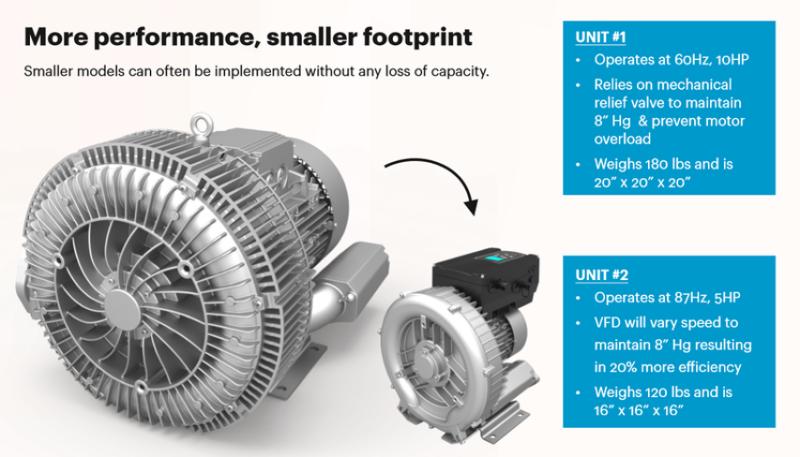

Replacement of standard motors with IE5 ultra-efficiency motors combined with VFD control

Improved insulation for machine barrels, heaters, and material transfer hoses

Dehumidifier optimization using dew-point-based automation and moisture isolation

Replacement of direct evaporative cooling with indirect evaporative air washers

Cycle-time optimization in moulding machines to reduce specific energy consumption

Pre-cooling of compressor suction air using chilled water

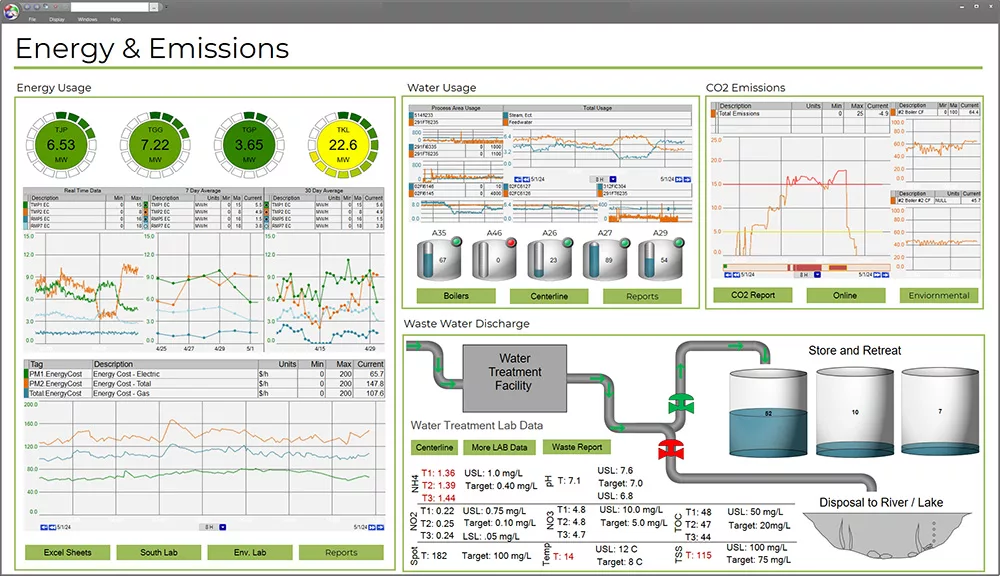

Utility system optimization for chillers, pumps, and cooling towers

4

Utility & Environmental Improvements

By reducing unnecessary moisture addition and optimizing airflow and cooling strategies, the facility achieved:

Lower dehumidifier load and stable humidity control

Reduced HVAC energy consumption

Improved shop-floor working conditions

Better process stability for injection moulding operations

The optimized systems were designed to adapt automatically to production load changes, ensuring sustained energy savings.

4

Results & Business Impact

The energy audit identified nine high-impact projects delivering:

~10% reduction in overall plant energy consumption

Over 52 lakh kWh of annual electricity savings

₹2.6+ crore per year in energy cost reduction

~4,000+ tons of CO₂ emission reduction annually

Project payback periods ranging from 4 months to 36 months

Improved equipment reliability and reduced maintenance stress

Increased production efficiency through optimized cycle times

A 12–18 month phased implementation roadmap was provided, enabling the client to prioritize quick-return projects while planning capital investments strategically.

Conclusion

This project highlights SEE-Tech Solutions’ expertise in delivering investment-grade energy audits for complex manufacturing environments. By combining deep process understanding, advanced technologies, and execution-ready solutions, SEE-Tech enabled the facility to achieve measurable cost savings, enhanced productivity, and long-term sustainability—without compromising operational performance.