The plastic industry is one of the most energy-intensive sectors, with utilities like chillers, compressors, air

handling units (AHUs), and pumps forming the backbone of production facilities. Rising energy costs and

increasing sustainability commitments make it essential for manufacturers to identify and adopt energy-efficient

technologies.

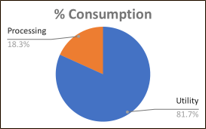

Plant Energy Consumption Data

Key Areas of Energy Consumption

| Chillers | Over one-third of total energy use |

| AHUs | Nearly one-fifth of energy consumption |

| Air Compressors & Pumps | Together add another significant share |

Energy saving in plastic production

- Chillers – Retrofitting with adiabatic cooling and VFDs on compressors can reduce energy use by more than 10%, without the high capital costs of new installations.

- Air Compressors – Pre-cooling and filtration solutions improve efficiency and reliability, reducing load and extending equipment life.

- Air Handling Units – Upgrading to advanced aerofoil plug fans with high-efficiency motors not only cuts power consumption but also improves airflow and reduces maintenance.

- Pumps – Optimization and retrofitting can achieve additional savings by aligning pump operation with process requirements.

Impact & Way Forward

By adopting a mix of retrofit technologies and process optimizations, plastic manufacturers can realistically

achieve 15–22% reduction in overall energy consumption. This translates into significant annual cost savings,

with typical payback periods of less than two years.

Beyond financial benefits, energy efficiency initiatives help the industry reduce carbon emissions and strengthen

its sustainability credentials. For manufacturers, the opportunity lies in implementing proven, implementable solutions that balance performance, cost, and environmental responsibility.